Productivity Analysis

New at the Motek: ProcessProductivityAnalysis

Diverse applications of our customers have lead us to develop hardware and software tools to analyse causes for downtime.

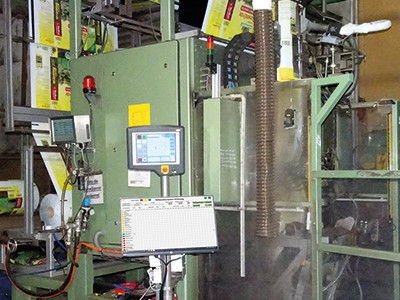

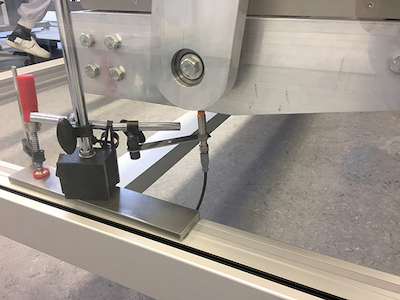

Set-up with hard & software

The productivity analysis has been already implemented in various fully automated and partly automated equipments and manual workstations.

The consistent recording of technical as well as of organizational reasons for downtime can lead to efficient shop floor management.

Application international pharmaceutical industry

Application packaging department

Actions to eliminate downtime can then be implemented and will lead to a lasting increase of productivity.

We developed our productivity analysis tool so that equipment and workplace data can be compiled temporarily or even on an ongoing basis.

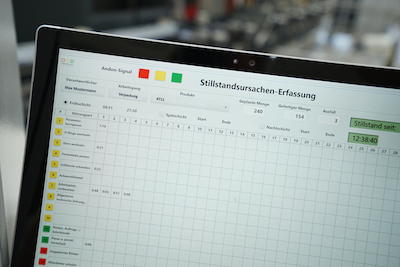

Easy consistent recording

Real-time analysis for efficient shop floor management

Due to the easy set-up, our hardware and software are also suited for the start-up of nonstandard machinery, especially during the launch phase.

Temporary set-up in all production areas

We look forward to meeting with you and to implement the initial set-up and configuration on-site.

- Digital and interactive communication in production and support areas

- Interface to Bosch Rexroth Communication Platform ActiveCockpit

- Information exchange via email, texts and apps (smartphone)

- Networking of business and production processes

- Dialog between worker, machine and product

- Current and consistent production key data

- Continuous capturing of production data

- Automatic escalation management

- Efficient shop floor management

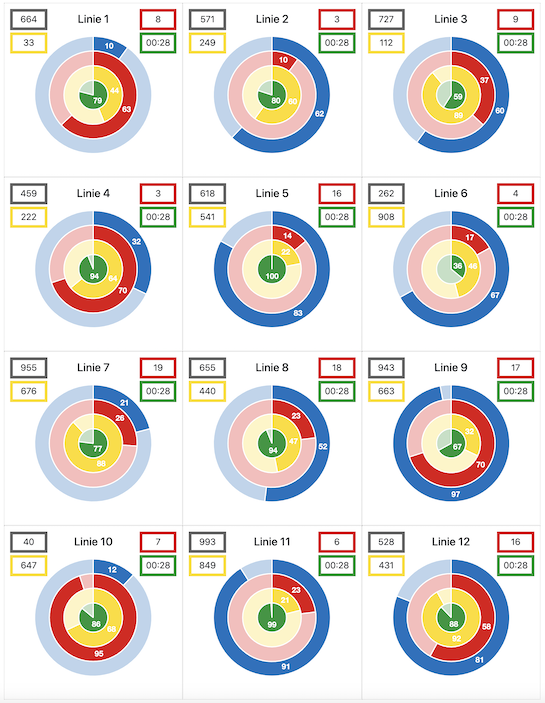

- Significant comparison of units

- Visualization of variations

- Identification of potentials in manufacturing processes

- Transparent and user-friendly setting

- Visualization of production key data

- Temporary set-up to handle current problems

- Fast decision-making possible when recognizing variations

- Interface to Microsoft Office Applications

- Customer-specific data analysis

- Integration in internal network

- Data base for Six Sigma analyses

- Adaption to customers needs

- Easy and fast installation

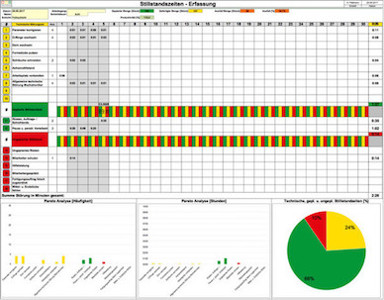

Logging of daily downtime

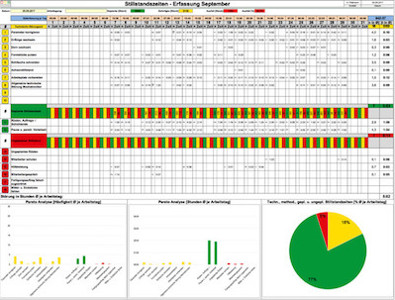

Monthly summary of data

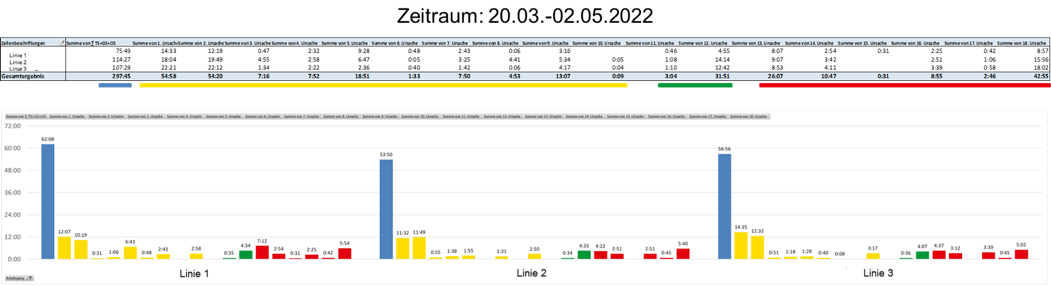

Line team shift comparison

Causes of downtime

Please find a summary of our ProcessProductivityAnalysis tool in our flyer.

English